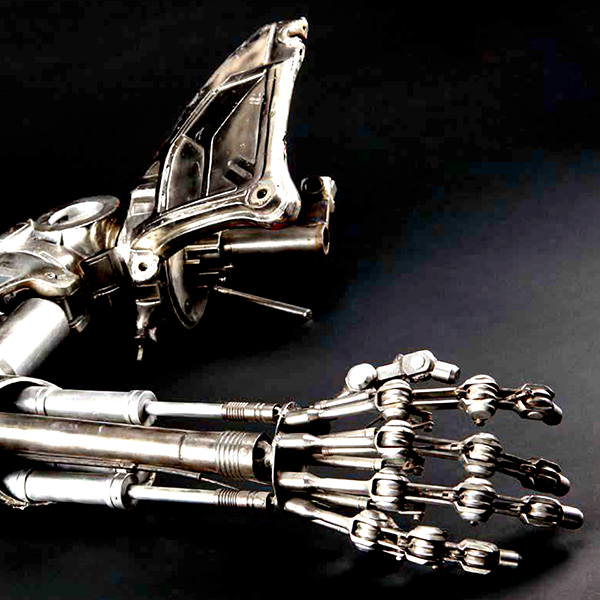

Walt Disney, intrigued with clockwork figures he had observed from Europe, had future Imagineers create a dancing mechanical man based on film the studio had of famous performer and dancer, Buddy Ebsen (who later played Jed Clampett on the TV Sitcom The Beverly Hillbillies). The clockwork miniature “dancing man” was the beginning of Walt Disney’s fascination with robotic actors he called “Animatronics.” The birds and flowers of the Enchanted Tiki Room, Mr. Lincoln, and the pirates and townspeople in the Pirates of the Caribbean are all the result of his interest.

Because they are driven by motors, pneumatics, and hydraulics, with mechanically abrupt starts and stops, it’s hard to make animatronics look natural like the smooth motions of coordinated muscles. That’s why programming animatronics to make them seem natural requires such finesse.

Think about this difference: imagine that you are tasked with programming a mechanical arm to place a cup on the table. By precise measurement, you know exactly how far mechanical muscles must contract to extend the arm to reach the table before the hand can let go. You enter those measurements and voila, the arm holding the cup reaches its destination precisely. Unfortunately, it starts abruptly, moves at that single predetermined speed until the measured destination and then stops just as suddenly in a jerky start-and-stop motion, sloshing the contents of the cup.

After the cup is in position, the “hand” opens. Then, after the hand has opened, it moves away to a predetermined resting place. Three distinct steps requiring three separate sets of movements, jerky and mechanical.

Contrast this with how our muscles work: we don’t know the precise measurement, so we start our arm moving toward the general vicinity of where we want to place the cup. As it nears the destination, our “feedback sensors”—our eyes, touch, and nerve receptors in the muscles themselves—tell us we’re getting close to the general vicinity, so we slow down for the sake of precision until, by those same feedback sensors we know the cup is touching the table. As soon as the cup starts to get close, we anticipate putting it down by beginning to loosen our grip on the cup. When the cup is down we finish releasing our grip, and at the same time we begin move our hand away. All three motions gracefully overlap, and there is a smooth deceleration and adjustment that occurs in each movement until the cup is down and our hand is away from it.

This has the further advantage of not spilling any cocoa!

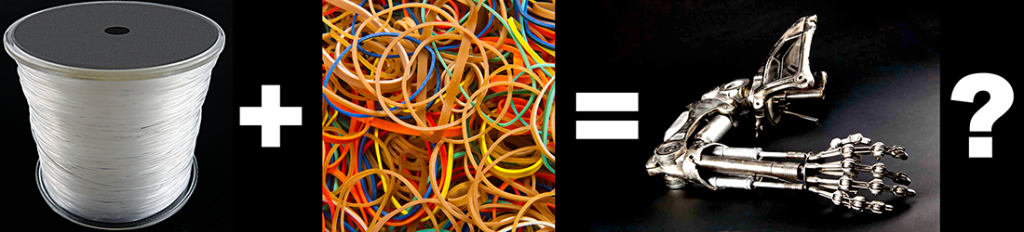

Animatronics might be more natural if the movements of the muscles were less mechanical and more natural; that is, if they had more natural starts and stops and built-in sensors to tell them how flexed they are. Some new and surprisingly inexpensive technologies on the horizon may replace those mechanical muscles: fishing-line and rubber bands.

In their report, “Artificial muscles from fishing line and sewing thread,” authors Carter S. Haines, et al, (2014) describe how they created muscles by super-twisting polymer fibers (= fishing line!). These hyper-twisted-fiber muscles can then contract by the application of heat, and relax as they cool.

In their report, “Artificial muscles from fishing line and sewing thread,” authors Carter S. Haines, et al, (2014) describe how they created muscles by super-twisting polymer fibers (= fishing line!). These hyper-twisted-fiber muscles can then contract by the application of heat, and relax as they cool.

These hyper-twisted-fiber muscles have several potential advantages for animatronics over mechanical robotics: 1) because they are responding to heating and cooling, they will tend to have more naturally smooth starts and stops as they contract and relax. 2) Because they are inexpensive single threads, they can be bound in bundles. Then, just like natural muscles, varying numbers of threads can be triggered as needed, adding even more finesse to movements. 3) Their inherent strength makes them perfect for the tight leverage required for some joints (think about the strength needed for muscles connected through the elbow joint to extend the arm in a pushup).

But, because they require heat to contract and cool to relax, how do we heat and cool them? In their experiments Haines and colleagues coated the fiber coils with silver and ran electricity through the silver to heat it up, and water to passively cool it down. Physics also suggests another method known as the Peltier effect which is able to move heat from one place to another—and back. Without going into too much detail, either some variation of the heating the researchers used, or one that uses the Peltier effect might be another way to create the contracting and relaxing effect of true muscles.

What about the feedback sensing? Our muscles have in them nerve sensors (called “proprioceptors”) that report back to the brain the relative positions of body parts by measuring the amount of tension in the muscles. Is there a technological equivalent?

Previous electronic sensors of this type tended to be of two types: “static switches,” like your home’s thermostat, that measure something, until it reaches a preset “on” or “off” point. Or, another like the knobs on a radio (called potentiometers), can be used to measure in amounts. Both of these tend to require mechanical parts to work.

Technology may have come to the rescue again! Scientists from the University of Surrey and Trinity College Dublin (Boland, et al, 2014) have combined wunder-material graphene with common rubber bands to make them electrically conductive. When connected to a power source, stretching the rubber bands measurably changes the current flowing thru them—even if the stretching movement is subtle.

Imagine your programmable Animatronic mechanical arm now with dozens of twisted-polymer muscle fibers, each with its own rubber band sensor, all of which are now under programmatic control. Programming would still be complicated, but natural movements would be built in to the hardware, rather than being something added on later in software.

By combining a set of conductive rubber bands with the fishing-line muscles, you could potentially build muscles that work almost like the real thing!

References:

Haines, Carter S., et al (2014). “Artificial muscles from fishing line and sewing thread” in Science (343:6173; pp. 868–872; 21 February 2014) (See http://www.sciencemag.org/content/343/6173/868)

Boland, Conor S., et al (2104). “Sensitive, high-strain, high-rate bodily motion sensors based on graphene-rubber composites” in ACS Nano. (8:9; pp. 8819–8830; 6 August 2014) (See http://pubs.acs.org/doi/abs/10.1021/nn503454h)

Photo Credits:

Nylon monofilament fishing line: adapted from product photo at www.aliexpress.com.

Colorful rubber bands: adapted from open-source photo in commons.wikipedia.com.org.

150-Yea-old Victorian prothetic arm: from www.sciencemuseum.org.uk.